An Isolation Valve is used in fluid management to stop the flow of process fluids in a pipeline, this is usually for maintenance or safety purposes.

A valve is classified as an isolation valve because of its intended function in a process pipe loop, not because of the design of the valve itself.

Importance of Isolating Valve

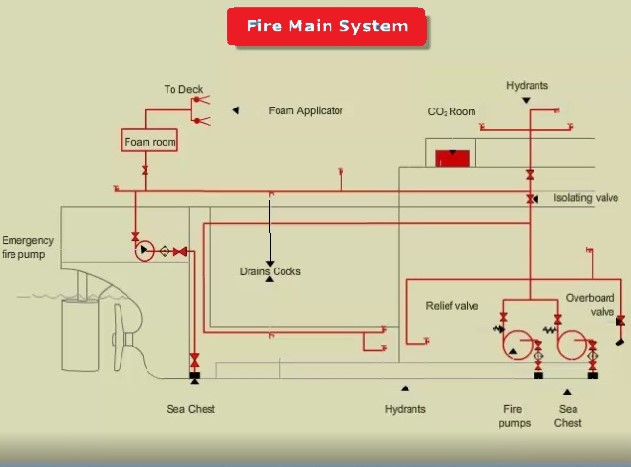

Isolating valves separate the section of the fire main within the machinery space containing the main fire pump or pumps from the rest of the fire main and shall be fitted in an easily accessible and tenable position outside the machinery spaces.

What are regulations for Isolation Valve on ships as per SOLAS?

The fire main shall be so arranged that when the isolating valves are shut all the hydrants on the ship, except those in the machinery space, can be supplied with water by another fire pump or an emergency fire pump.

The emergency fire pump, its seawater inlet, suction, delivery pipes, and isolating valves shall be located outside the machinery space.

Location of Isolating Valve on board Ship

On oil and fuel oil tankers, isolation valves shall be fitted in the fire main at the poop front in a protected position and on the tank deck at intervals of not more than 40 m to preserve the integrity of the fire main system in case of fire or explosion.